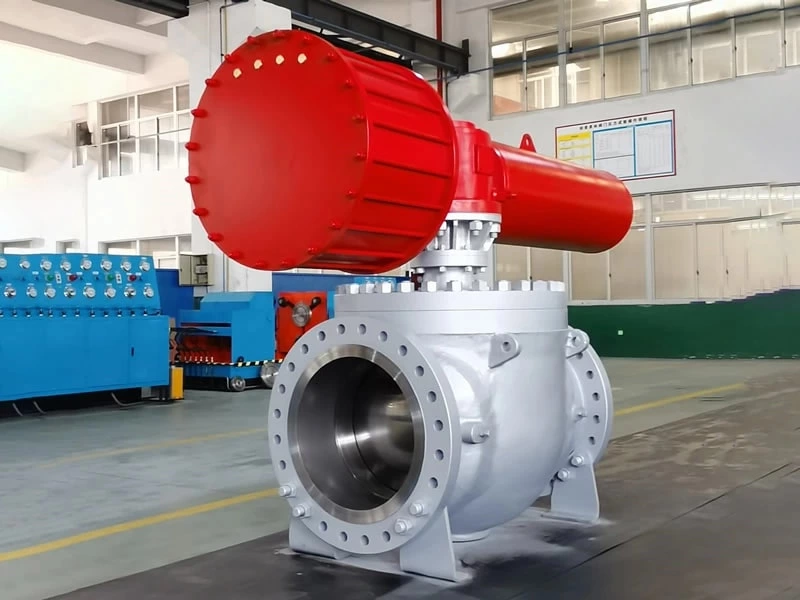

Trunnion Ball Valve

Relia trunnion ball valves are available in 2pc or 3pc body side entry, top entry, and fully welded design, with soft or metal seated. Trunnioin ball valves are designed as per API 6D, and fire safe tested as per API 607.

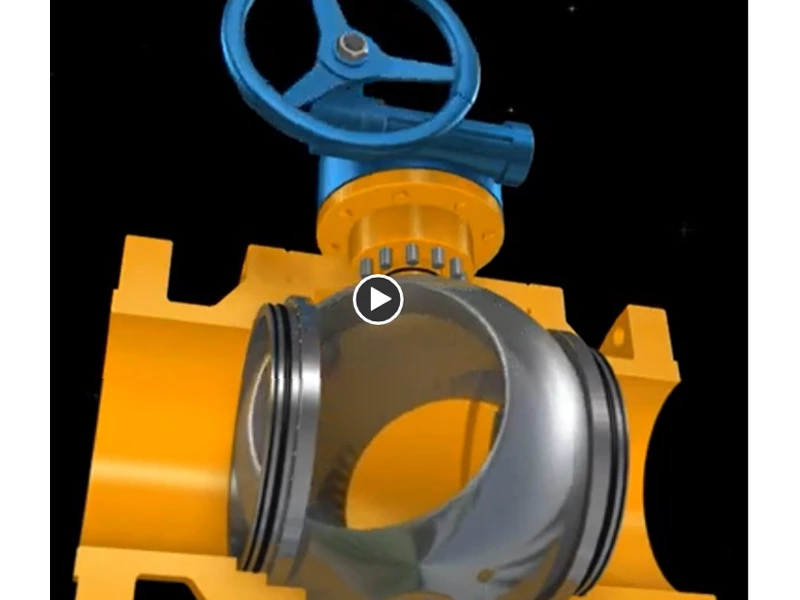

The trunnion ball valve is designed with a ball held by the stem at the top and by a shaft called a trunnion at the bottom. The combination of trunnion-mounted balls and unique spring-loaded upstream sealing provides bubble-tight seal and low operating torques, even at extremely high shut-off pressure.

Trunnion mounted ball valves are available in a wide range of cast and forged carbon steel, stainless steel, duplex stainless steel; size up to 48", pressure rating up to ANSI Class 2500.

General Features and Benefits

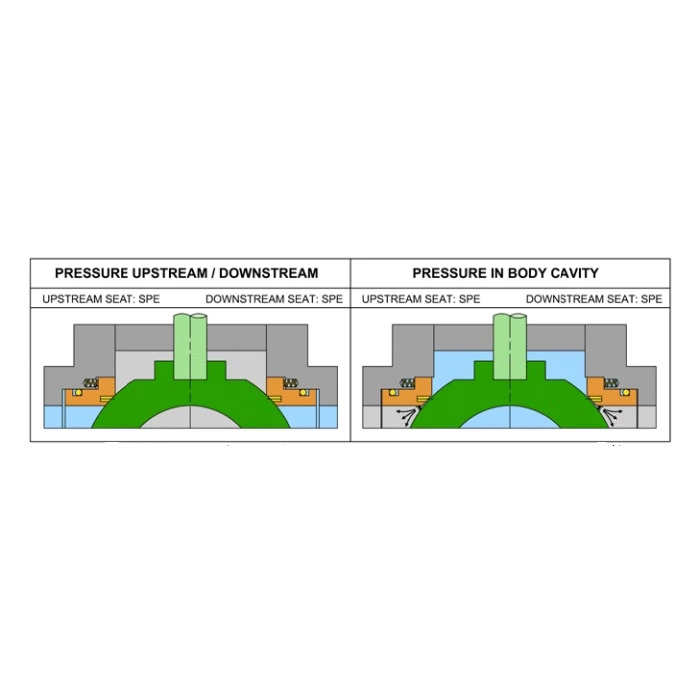

- Double block and bleed: Each seat blocks the flow from each side.

- Cavity over-pressure self-relieving: Over-pressure in the body cavity will pop the seats off the ball surface, and excess pressure will be relieved into the pipeline. After the pop-off action, the seats will return to their normal position, in contact with the ball.

- Body and bonnet sealing: gasket and O-ring seal to guarantee the sealing performance at high and low pressure conditions.

- Leakage rate: ISO 5208/EN 12266-1 Rate A (zero visual leakage)

- Fire-safe design to API 607/API 6FA

- Anti-static design: A static conduction spring is used as standard between the stem and the ball.

- Anti-blow-out stem

- Low-operation torque design

Options

- Double piston effect seat (DIB-1, DIB-2)

Design Features

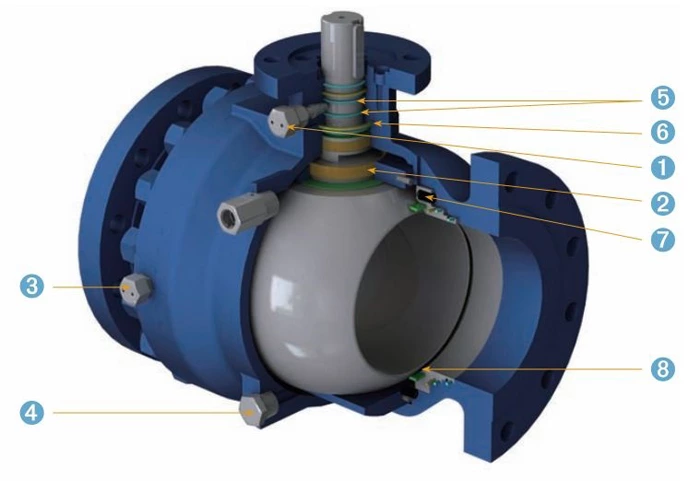

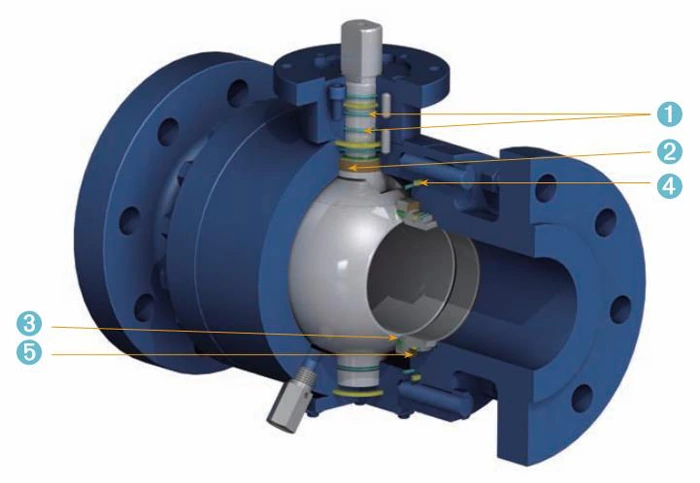

Cast Steel Trunnion Ball Valve Design Features

① Emergency Sealant Injection Fitting: Prevents leakage from the stem.

② Blow-out Proof Stem: Stem functions as the backseat to assure stem sealing at all pressures.

③ Emergency Sealant Injection Fitting: Prevents leakage from the seat.

④ Drain plug:Relieves the body cavity.

⑤ Double Sealing O-rings:Prevents leakage from stem area.

⑥ O-ring & Gasket Combination:Prevents leakage from body connection area.

⑦ Floating Seat: Spring loaded seats assure sealing, even at low pressures.

⑧ Metal-to-Metal Sealing: When soft seals are deteriorated by fire, seat float to shut of the line fluid.

Forged Steel Trunnion Ball Valve Design Features

① Two O-ring seals prevent leakage from the stem area.

② Blow-out-proof stem: a safety feature that functions to assure stem sealing at all pressures.

③ Back-up metal-to-metal Sealing: When primary soft-seat material is deteriorated by fire, the metal-to-metal seat provides shutoff.

④ O-ring and Gasket Combination: Prevents leakage from the body connection area.

⑤ Floating spring-loaded seats: ensure sealing even at low pressures.

Explosive Drawing & Material Specifications

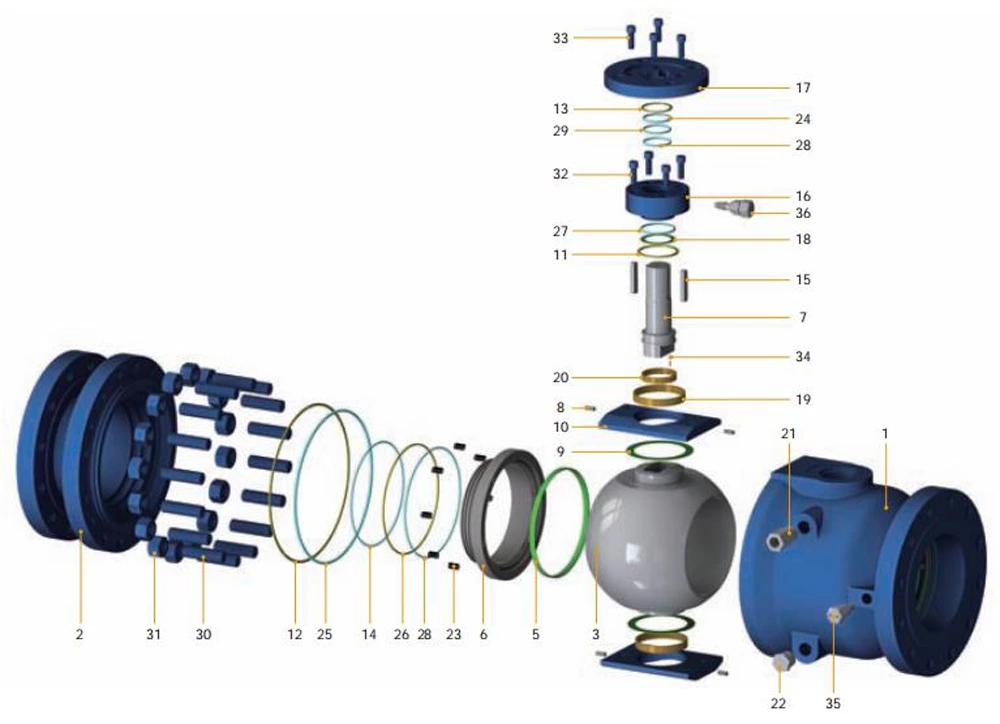

Cast Steel Trunnion Ball Valve Drawing

Material Specifications of Cast Steel Trunnion Ball Valve

| No | Part | Carbon Steel | Stainless Steel | Sour Service | Low Temperature Service |

|---|---|---|---|---|---|

| 1 | Body | ASTM A216-WCB | ASTM A351-CF8M | ASTM A216-WCB | ASTM A352-LCB |

| 2 | Body cap | ASTM A216-WCB | ASTM A351-CF8M | ASTM A216-WCB | ASTM A352-LCB |

| 3 | Ball | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350-LF2/ENP |

| 4 | Seat Assembly(5+6) | 5&6 | 5&6 | 5&6 | 5&6 |

| 5 | Seat Insert | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK |

| 6 | Seat Ring | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350-LF2/ENP |

| 7 | Stem | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350-LF2/ENP |

| 8 | Trunnion Alignment Pin | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 9 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 10 | Trunnion Support | ASTM A588B/ENP | ASTM A351-CF3M | ASTM A588B/ENP | ASTM A588B/ENP |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 12 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 13 | Fire Safe seal | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 14 | Fire Safe seal | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 15 | Key | Carbon Steel | Stainless Steel | Carbon Steel | Stainless Steel |

| 16 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350-LF2 |

| 17 | Top Flange | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350-LF2 |

| 18 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 19 | Bearing | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 |

| 20 | Bearing | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE |

| 21 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 22 | Drain | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 23 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 24 | O-Ring | NBR | NBR | NBR | NBR |

| 25 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 26 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 27 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 28 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 29 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 30 | Body Stud | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 31 | Body Nut | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7M |

| 32 | Screw | ASTM A193-B7 | Stainless Steel | ASTM A193-B7M | ASTM A320-L7M |

| 33 | Screw | ASTM A193-B7 | Stainless Steel | ASTM A193-B7M | ASTM A320-L7M |

| 34 | Anti-Static Device | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 35 | Injection | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 36 | Injection | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

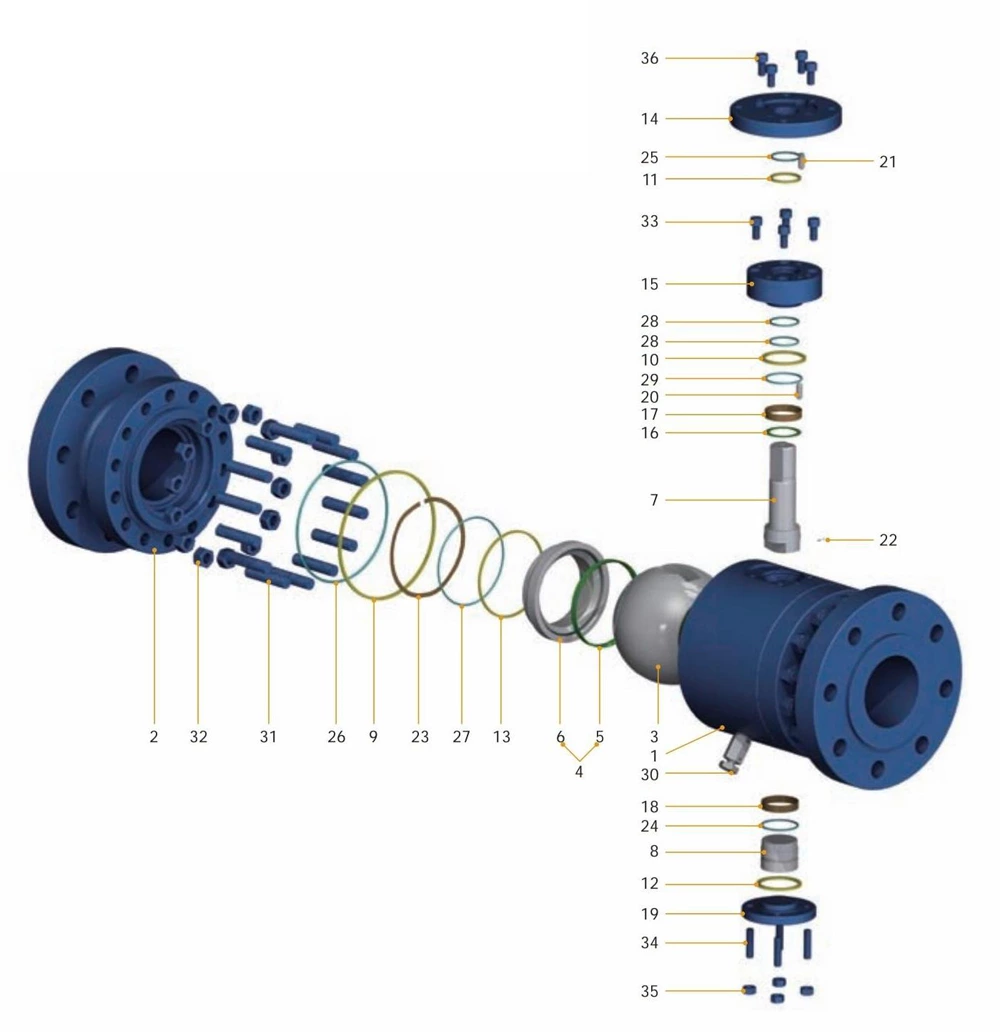

Forged Steel Trunnion Mounted Ball Valve Drawing

Material Specifications of Forged Steel Trunnion Ball Valve

| No | Part | Carbon Steel | Stainless Steel | Sour Service | Low Temperature Service |

| 1 | Body | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 2 | Body cap | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 3 | Ball | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350 LF2/ENP |

| 4 | Seat Assembly(5+6) | 5&6 | 5&6 | 5&6 | 5&6 |

| 5 | Seat Insert | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK |

| 6 | Seat Ring | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350 LF2/ENP |

| 7 | Stem | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350 LF2/ENP |

| 8 | Trunnion | ASTM A182 F6a | ASTM A182 F316L | ASTM A182 F6a | ASTM A182 F6a |

| 9 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 10 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 12 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 13 | Fire Safe seal | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 14 | Top Flange | ASTM A105N | ASTM A182 F304 | ASTM A105N | ASTM A350 LF2 |

| 15 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 16 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 17 | Bearing | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 |

| 18 | Bearing | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE |

| 19 | Cover | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 20 | Pin | Carbon Steel | Stainless Steel | Carbon Steel | Carbon Steel |

| 21 | Pin | Carbon Steel | Stainless Steel | Carbon Steel | Carbon Steel |

| 22 | Anti-Static Device | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 23 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 24 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 25 | O-Ring | NBR | NBR | NBR | NBR |

| 26 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 27 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 28 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 29 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 30 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 31 | Body Stud | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 32 | Body Nut | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7M |

| 33 | Screw | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 34 | Body Stud | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 35 | Body Nut | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7M |

| 36 | Screw | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |